Snippets from my time spent as the:

WWU Industrial Design Manager

In the studios & Classrooms: Work time & Critiques

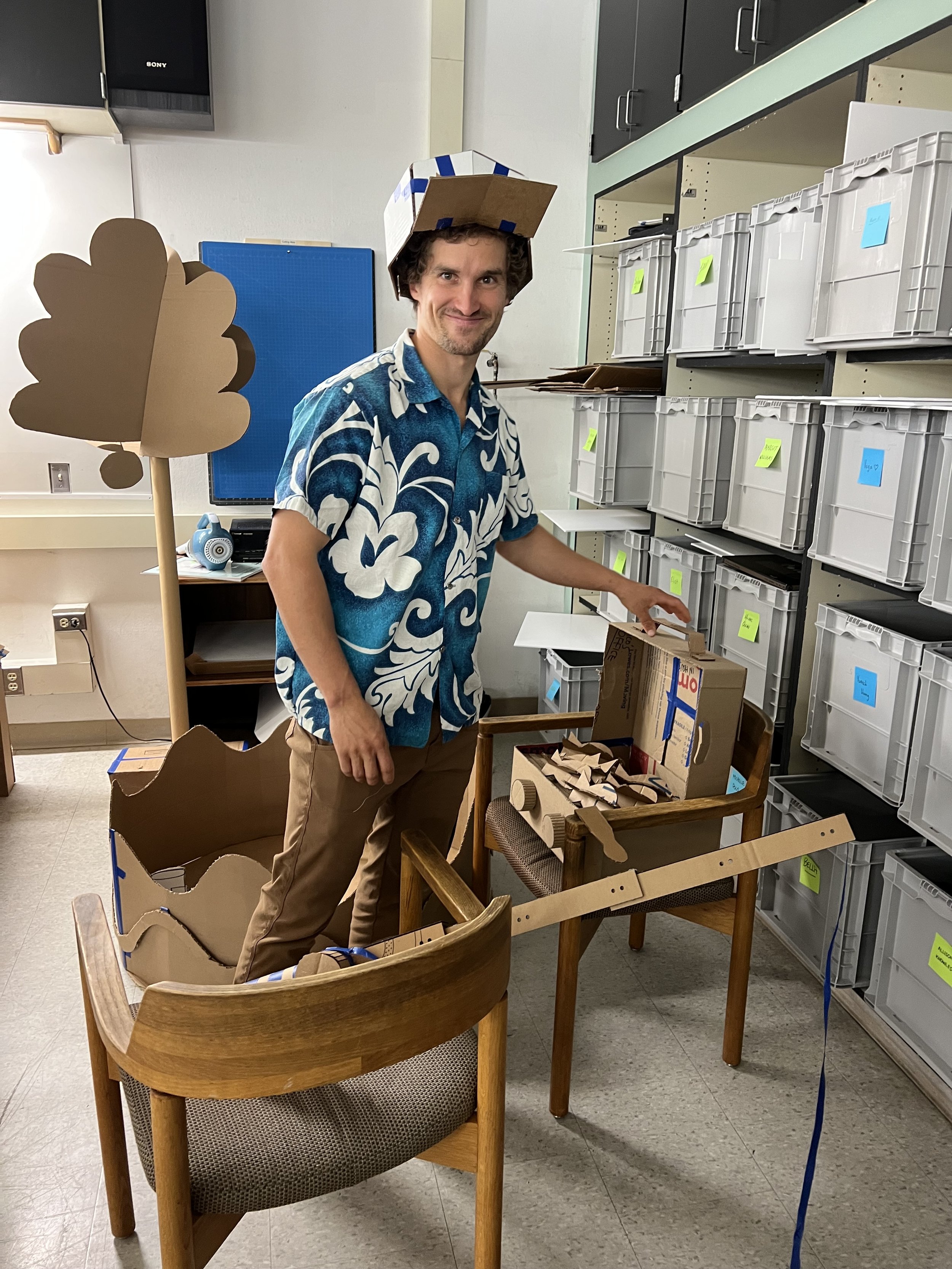

Students created "experiences" out of cardboard. Other students then tested them without explanation.

Students created "experiences" out of cardboard. Other students then tested them without explanation.

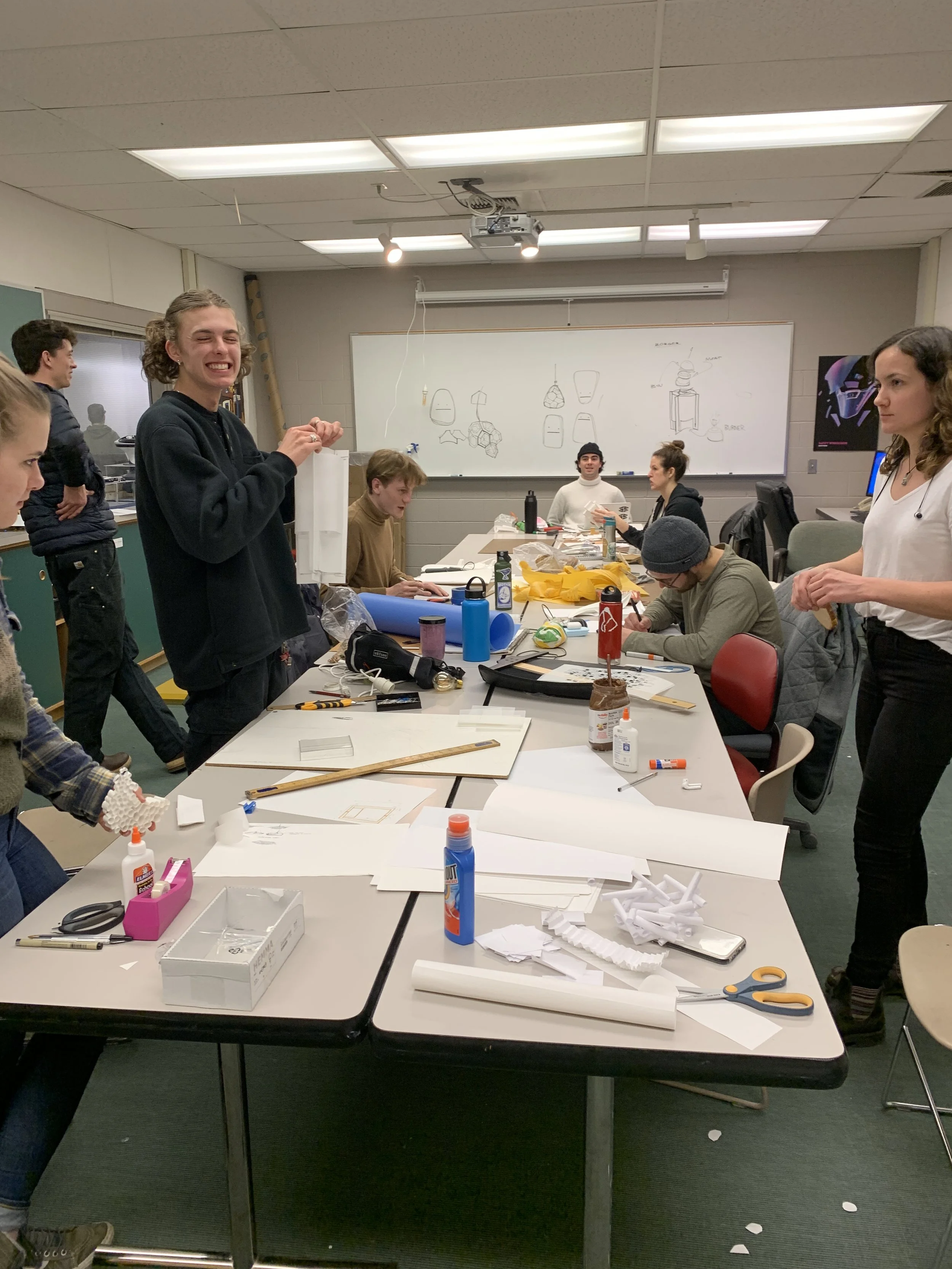

Sophomore pendant lighting critique.

Discussing polyurethane models with the sophomores.

Sophomore pendant lighting critique.

In class work time shenanigans.

In The Shop: This & That

Terra tearing it up on the mill.

Helping Terra use the mill to route out a unique shape in wood for her aluminum & wood pencil organizer.

A happy & proud Terra after some tedious time spent on the mill.

Laser cutting custom pegboard with Noah for the build out of the WWU Engineering & Design Makerspace.

Creative fixturing on the mill to drill a hole in already shaped aluminum for Thomas's aluminum & wood container.

Working with Jo to CNC route internal wood frame components for her senior thesis furniture project.

Seanna on the metal lathe adding a hole in turned wood salt & pepper shaker.

Austin on the planer.

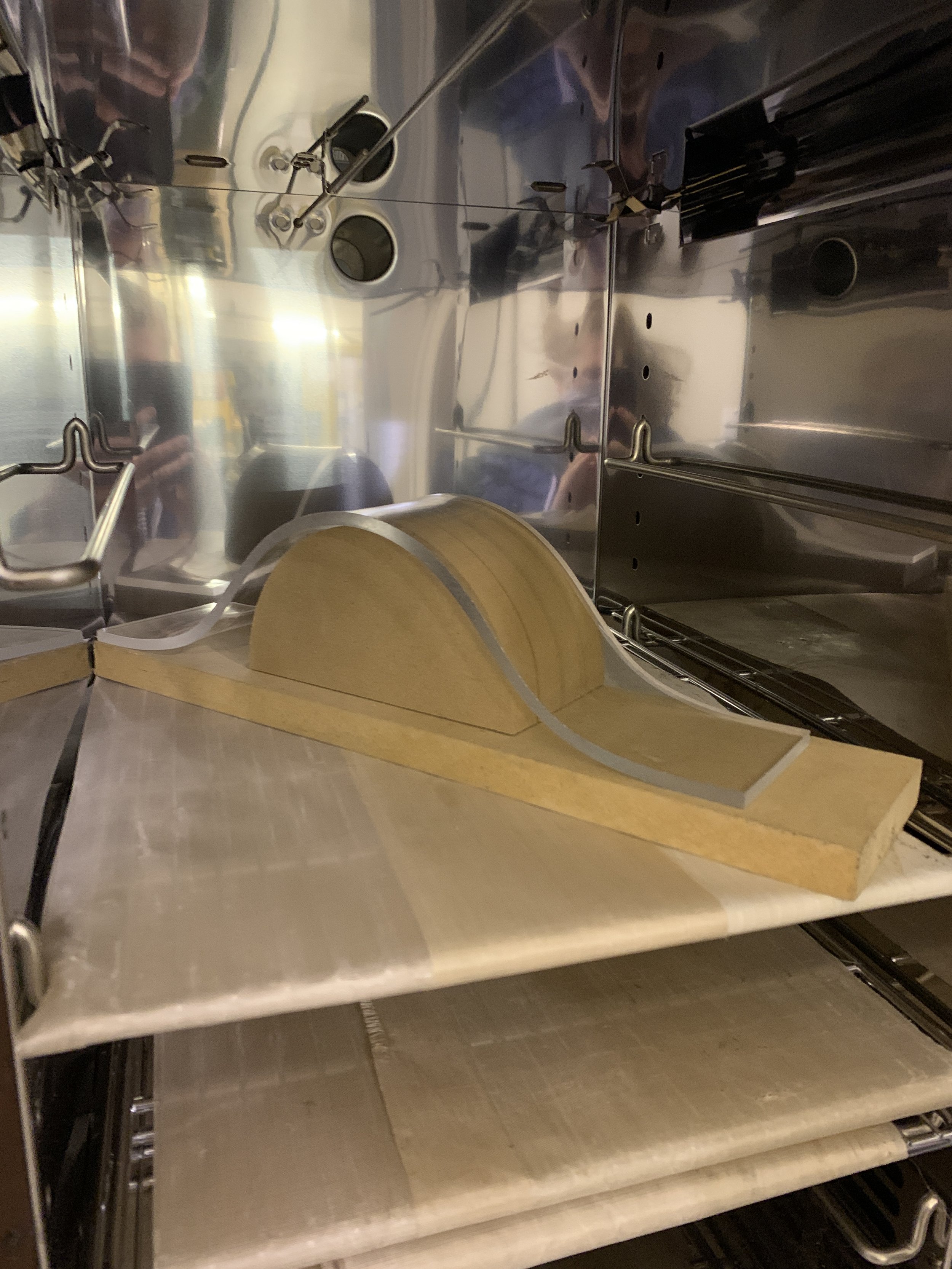

Demonstrating the limits of slump molding acrylic in an oven.

Keaton's impressive ability to make a mess the size of any space he is in.

Helping Maddie mill wood for their salt & pepper shaker set.

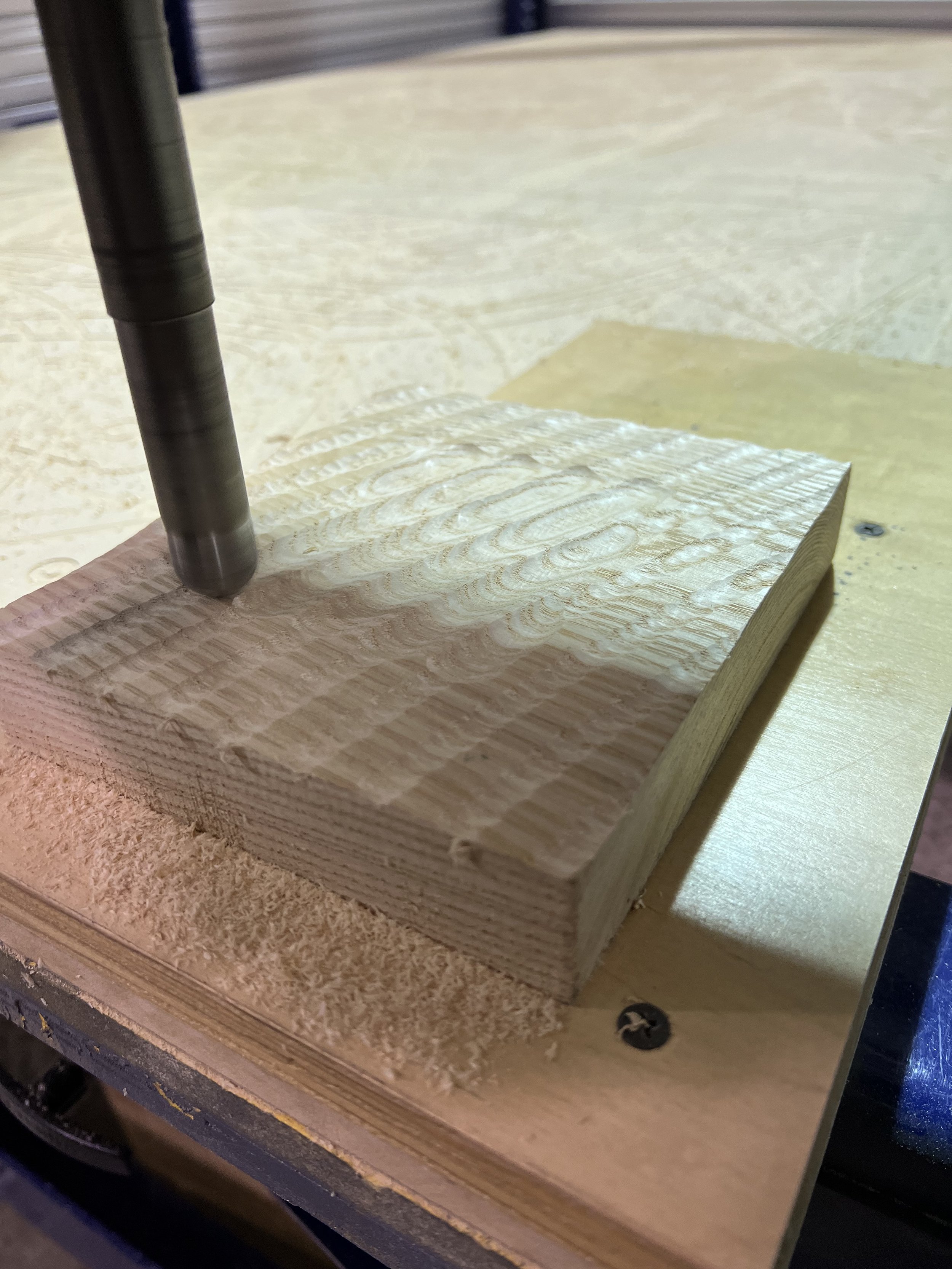

Pockets being added to wood on the mill.

Surfacing a texture sample for Ashayla.

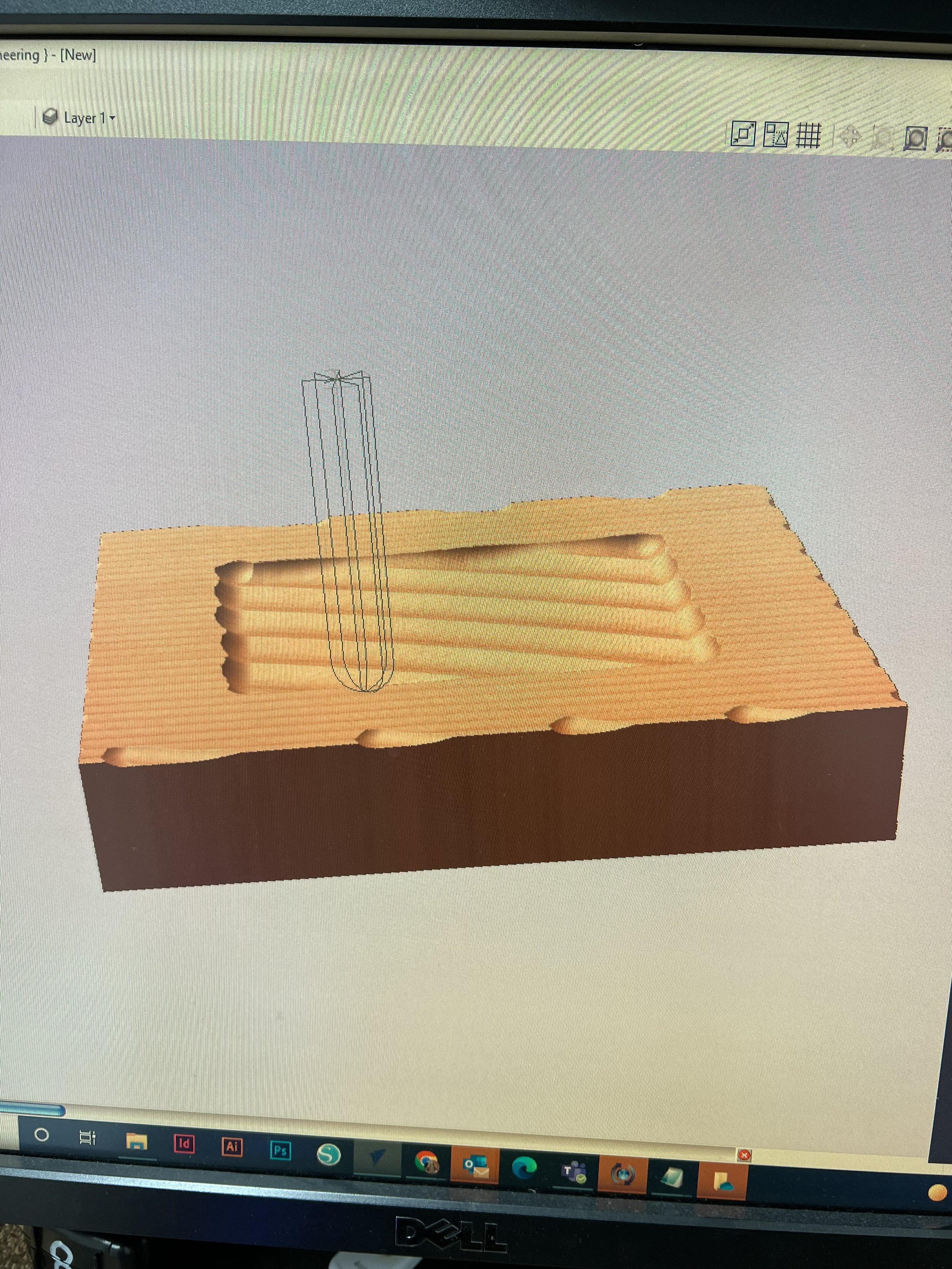

Programming the cut path for a texture sample for Ashayla.

Surfacing layered up XPS insulation foam.

Keaton on the sliding miter saw after a refresh on safe use.

Jo making sketch models out of XPS foam on the hot wire cutter.

In the Shop: 2022 Senior Thesis Furniture Projects

Wylie keeping tabs on the Shopbot while it cuts out components for his senior thesis furniture set.

Matthew supervising the Shopbot's progress surfacing the seat & back panels for his chair.

Surfacing ash on the CNC router.

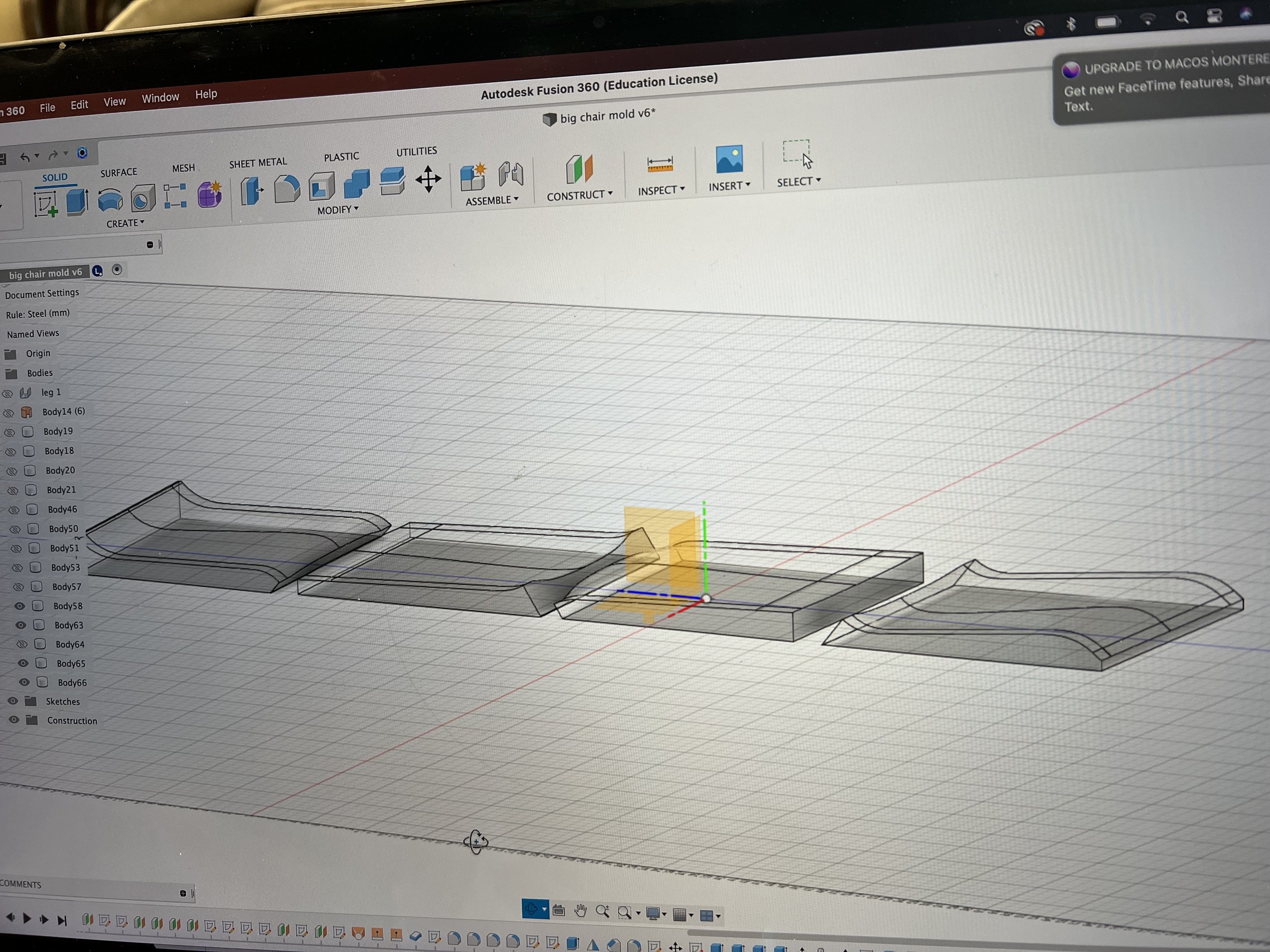

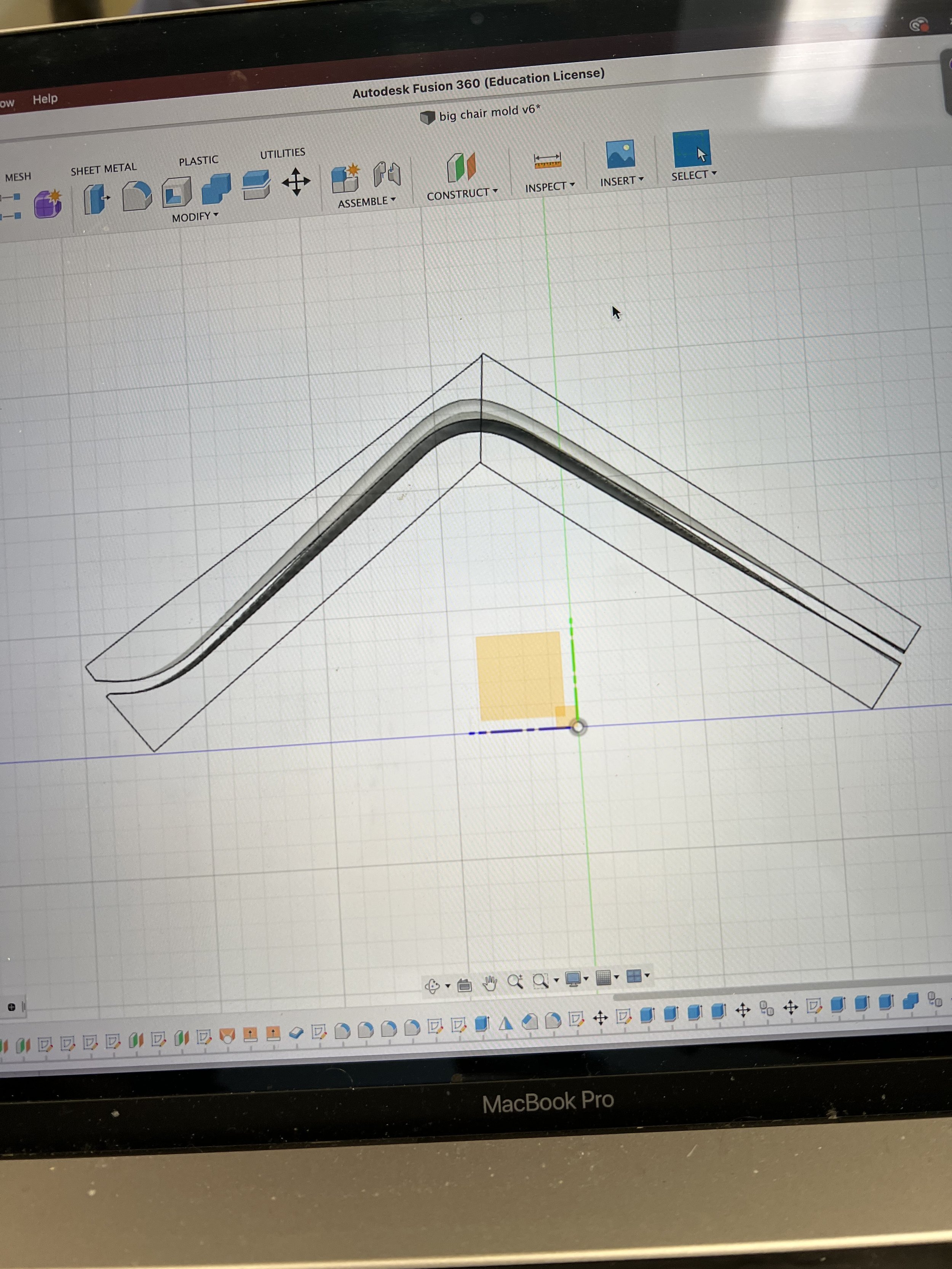

Behind the scenes of planning the mold for Lili's polycarbonate chair.

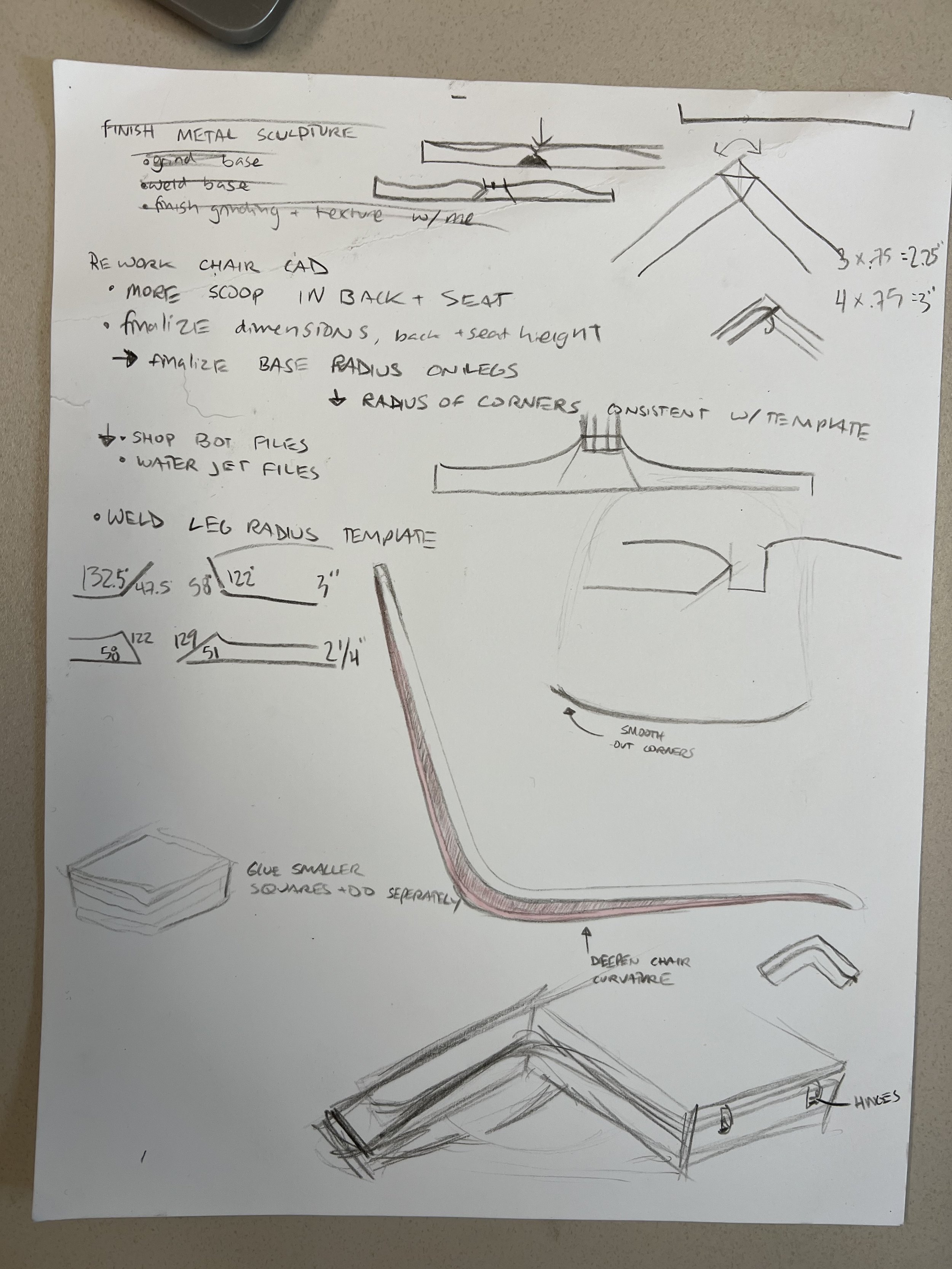

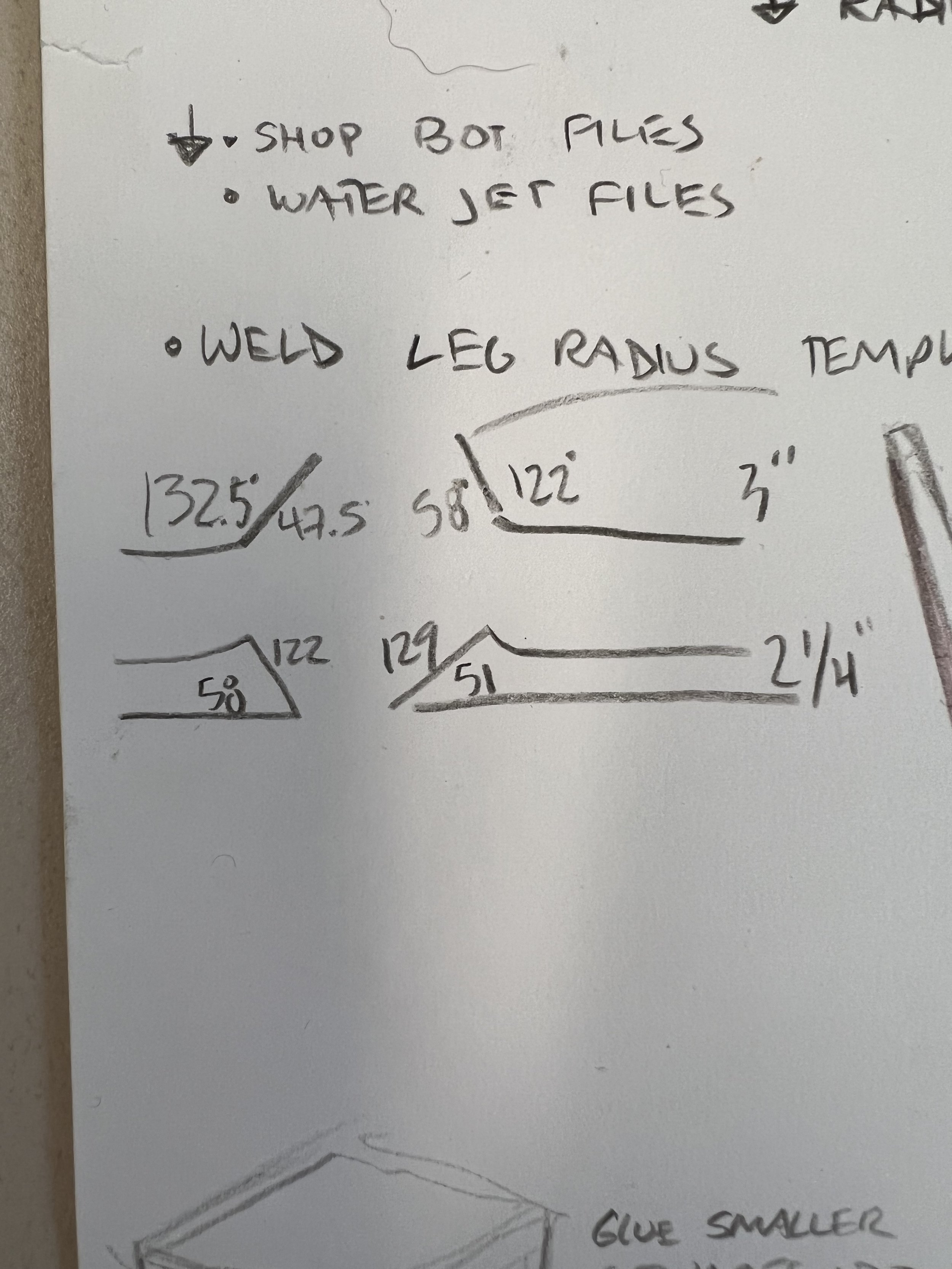

The joy of angles & math.

Reviewing Lili's mold parts for her polycarbonate chair.

Lili's mold parts in position.

Helping Lili plan & cut angles into her MDF mold blanks before being put on the Shopbot for surfacing.

Spreading wood glue on the front & backside of preformed veneer.

Stacking up the glue covered layers of veneer in Bri's MDF mold.

Adding glue to any dry spots & attempting to keep the layers from shifting too much before adding the top half of the mold.

Using a hydraulic press to compress the layers of veneer & glue inside the MDF mold in order to tighten the ratchet straps.

Bri's custom plywood all smooshed in her MDF mold & ready to slowly dry.

Bri making calculations for assembling her custom made plywood chair components.

Working with the manufacturing lab manager to make a vertical cut in a tall tube for a crossbar support in Bri's chair.

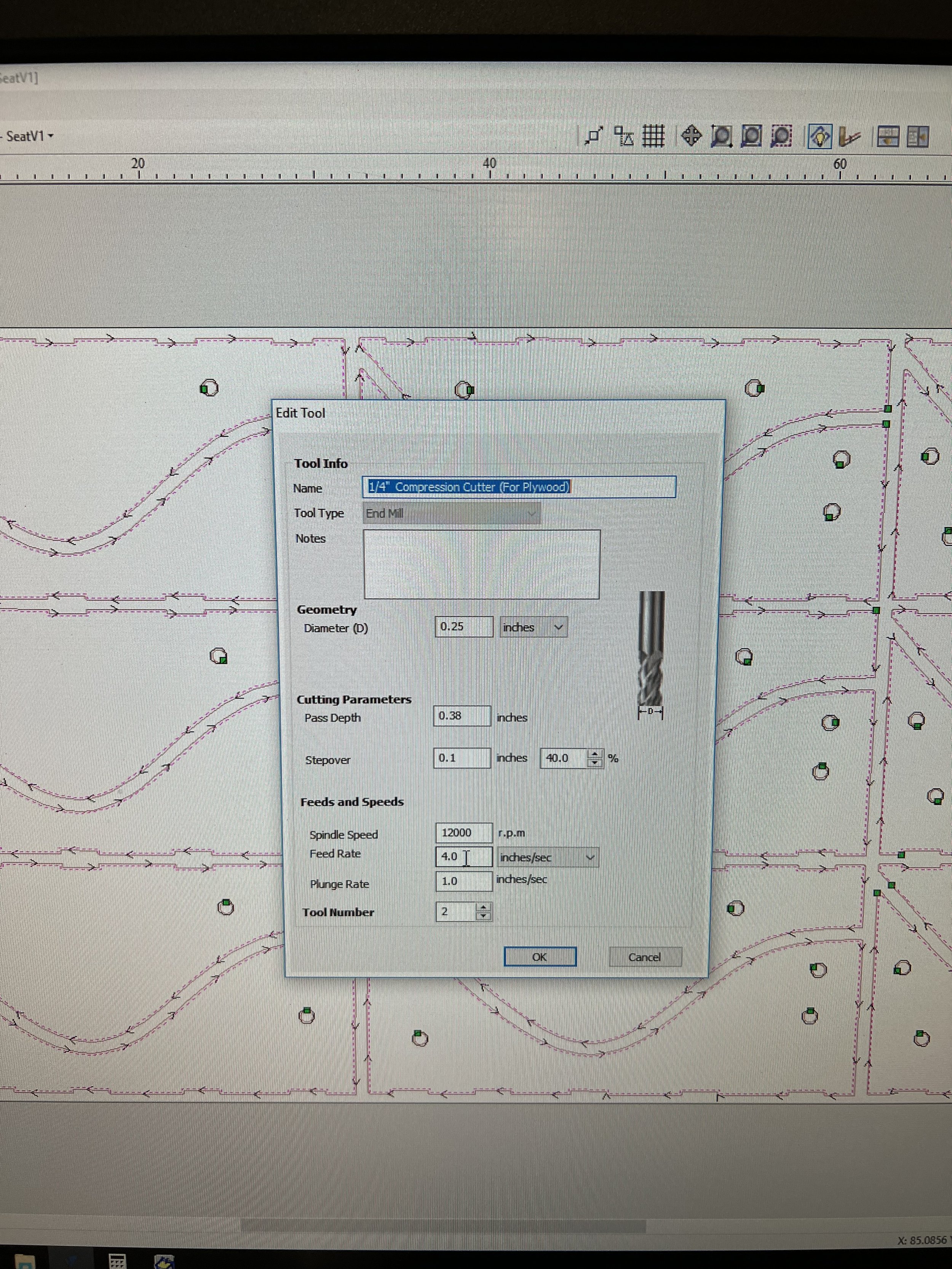

Setting up the cut paths for Rafer's MDF mold used to also make his own plywood.

Rafer making a test piece of his chair base by using a narrow version of his mold.

Rafer going through the same steps of layering preformed veneer & glue to make his own plywood.

Rafer relieved to have his chair seat on the way to completion.

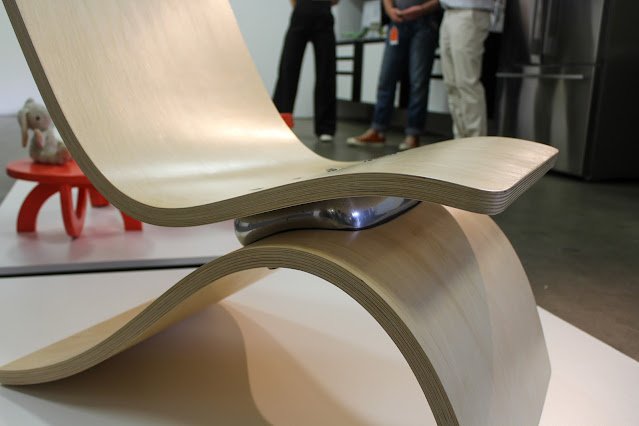

At the show: 2022 Senior Thesis Furniture Projects

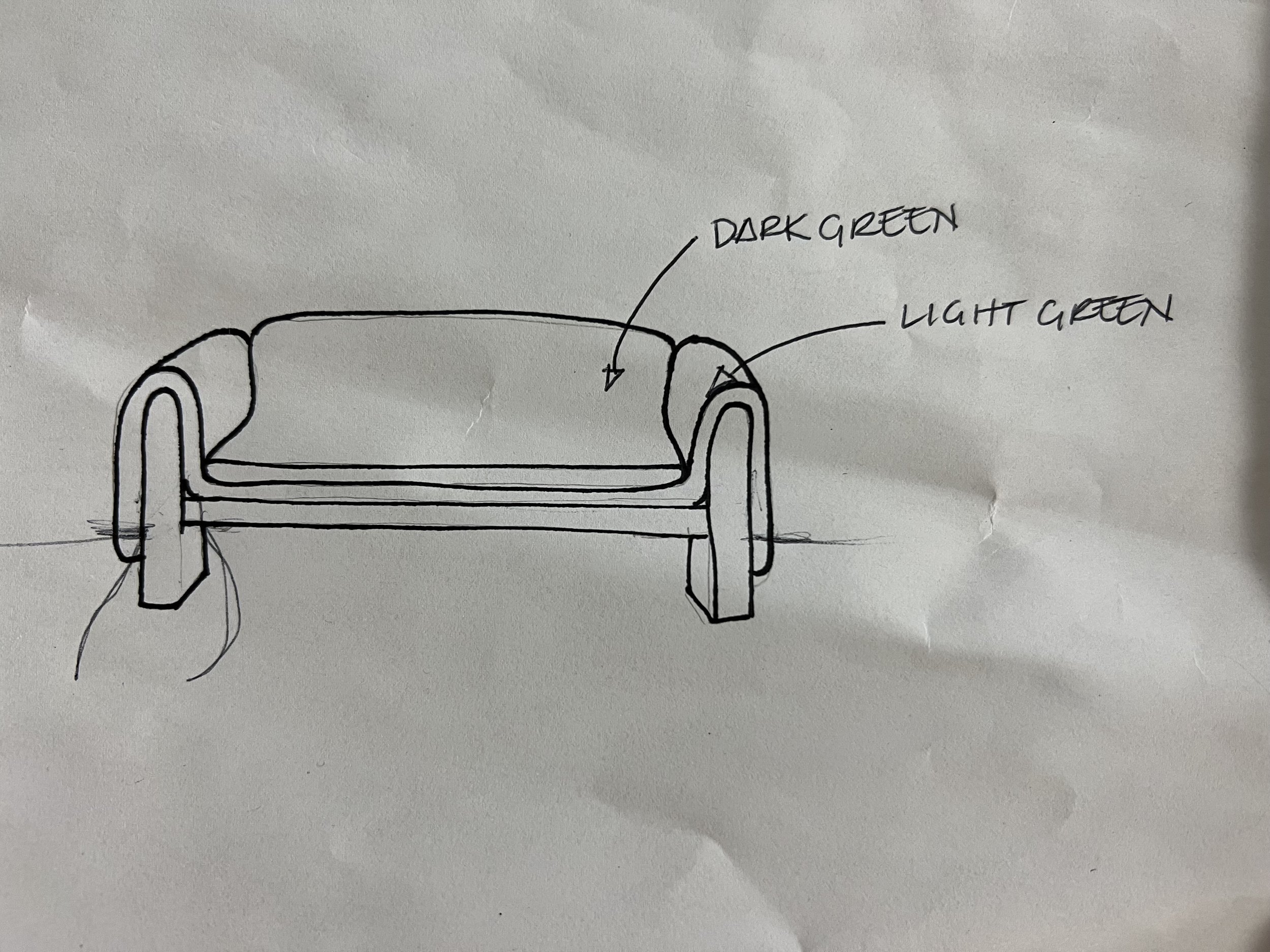

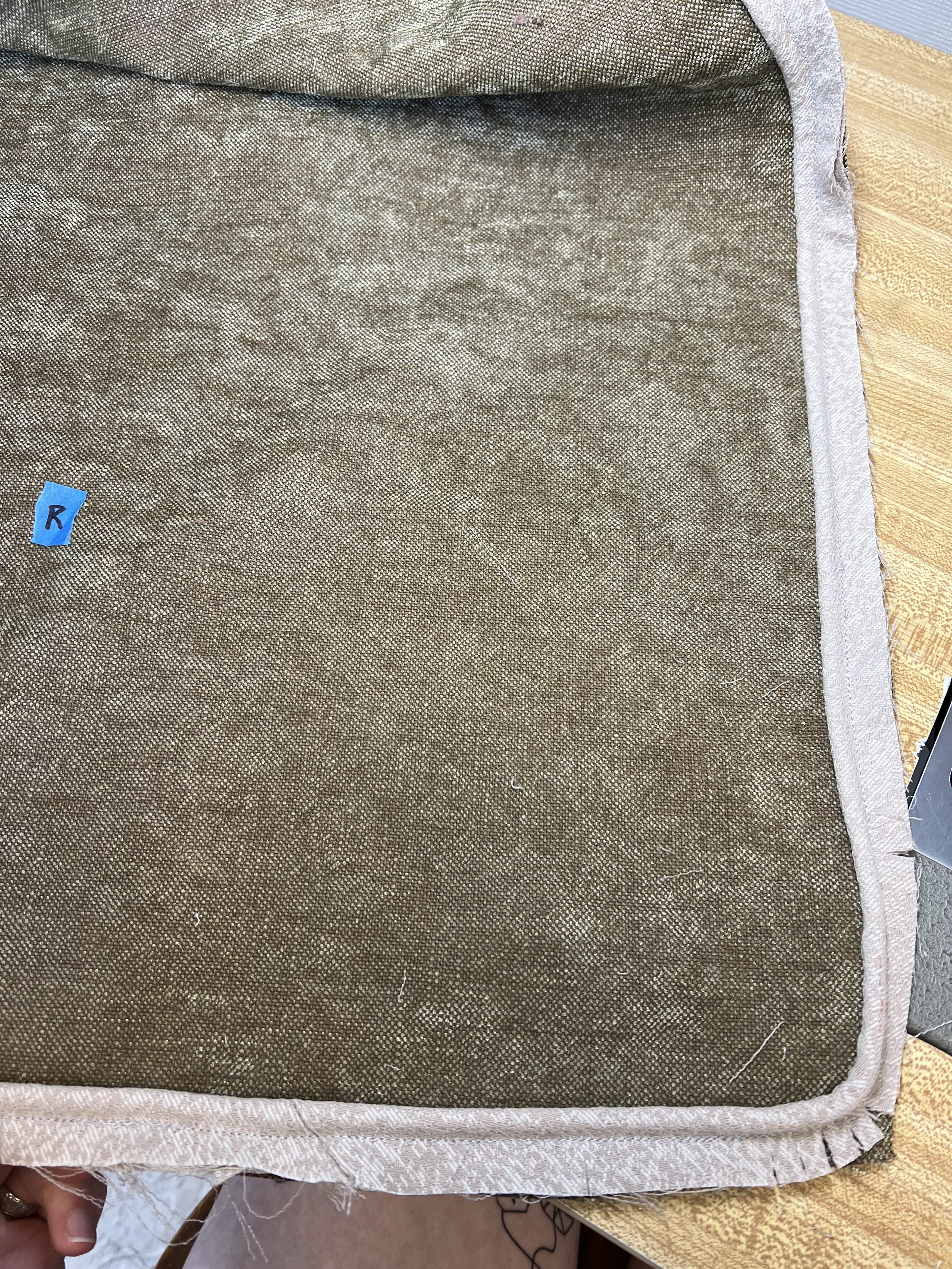

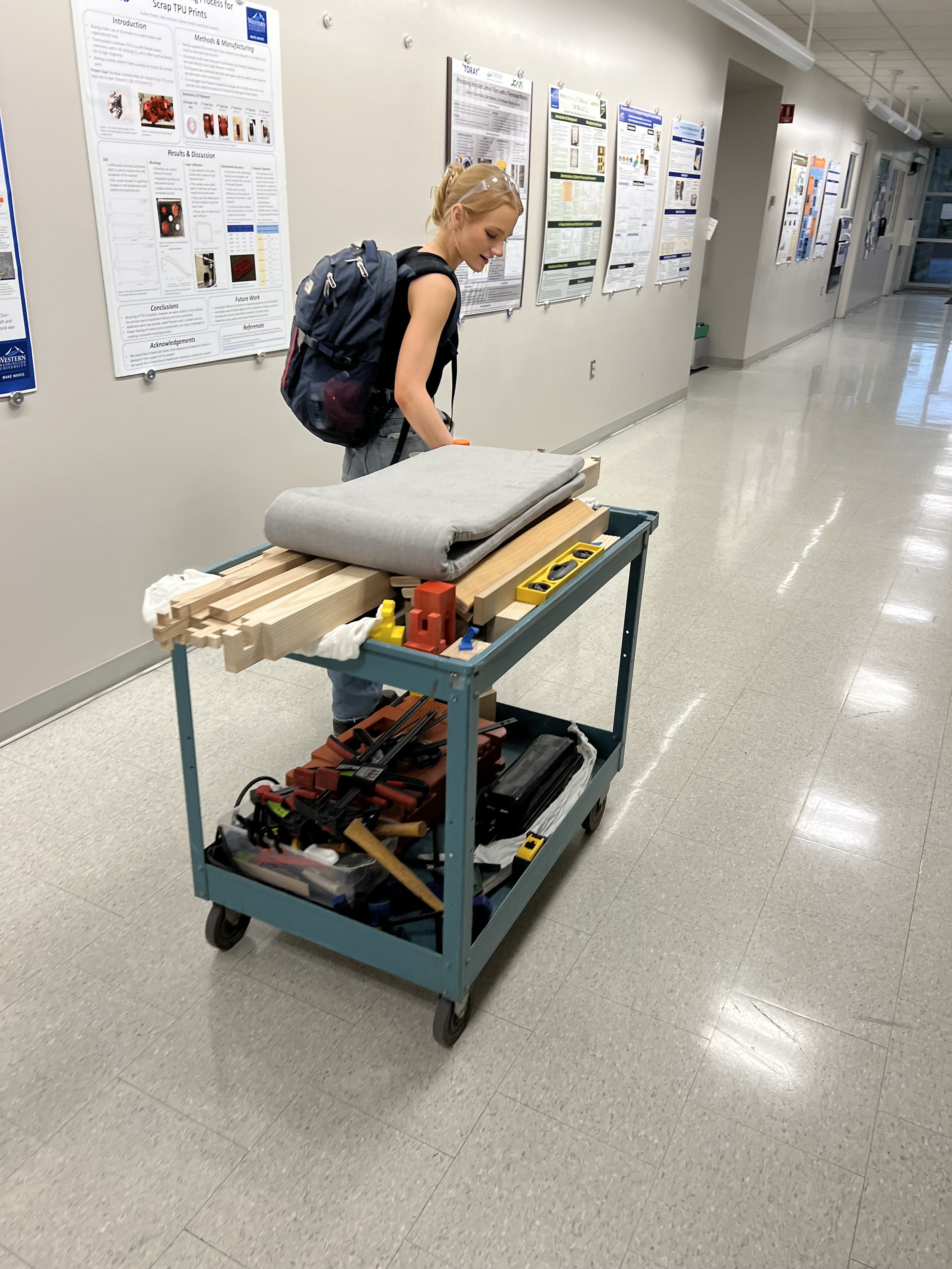

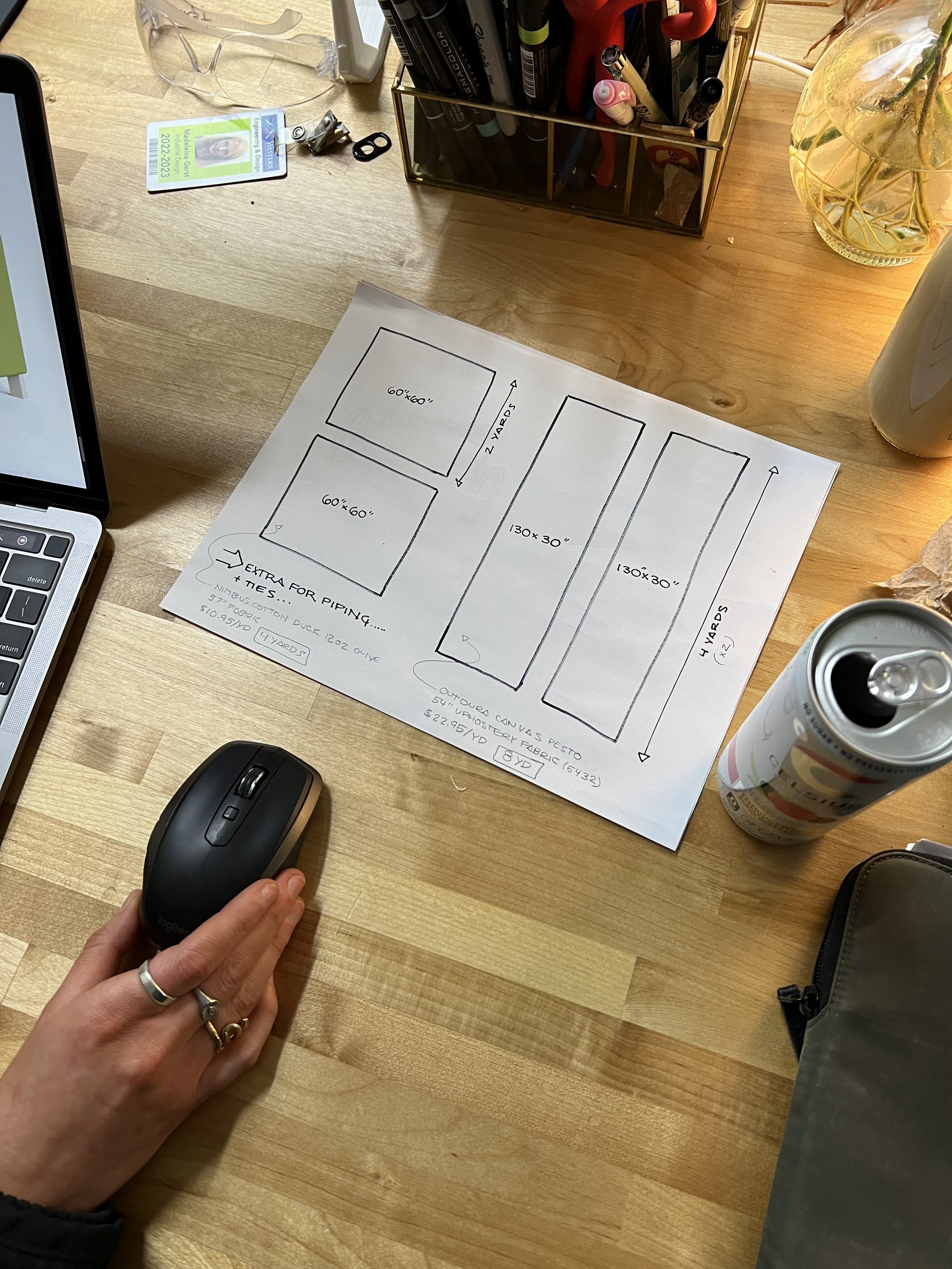

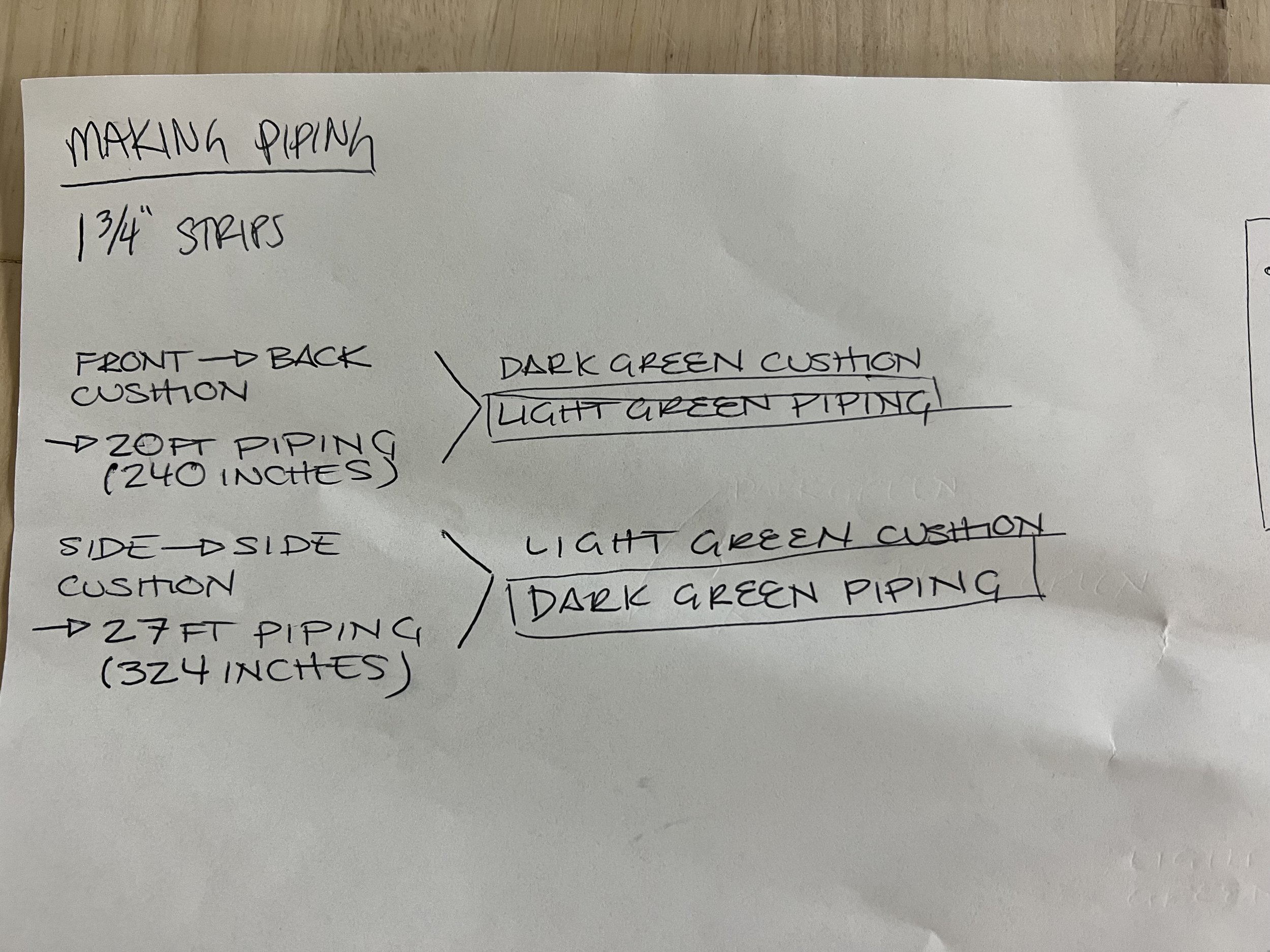

LOVESEAT: 2023 Senior Thesis Furniture Project by Madeleine Gerst